Understanding the Plastic Injection Molding Process for High-Quality Production

Key Benefits of Making Use Of Plastic Injection Molding in Production

Plastic injection molding has arised as a critical strategy in the production market, providing a range of advantages that dramatically improve manufacturing procedures. Noteworthy benefits include impressive manufacturing effectiveness, the capability for detailed designs, and a favorable cost structure that appeals to services of all dimensions.

High Production Performance

One of one of the most substantial advantages of plastic injection molding is its high production performance, which can lead to the rapid manufacturing of countless similar components within a short timeframe. This effectiveness is mostly credited to the automatic nature of the shot molding procedure. When the first setup and mold development are completed, the production of parts can be scaled up substantially without a matching rise in labor expenses or time.

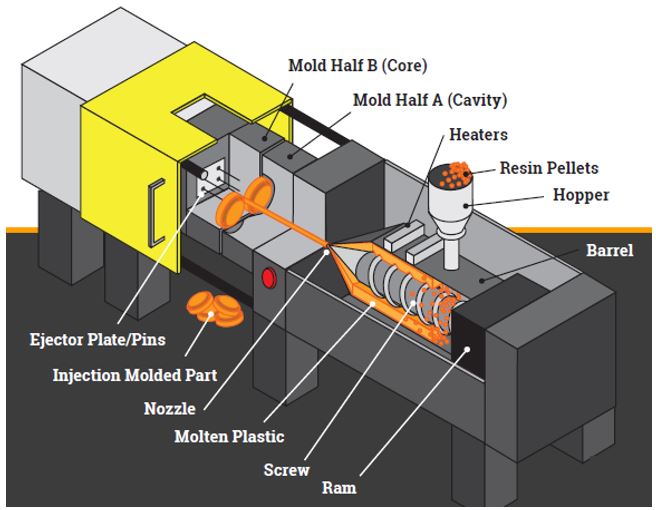

The process usually includes home heating plastic pellets until they melt, injecting the molten product right into a precisely created mold and mildew, and allowing it to cool and solidify - Plastic Injection Molding. This cycle can be finished in plain seconds to mins, relying on the complexity and size of the part being produced. As an outcome, makers can achieve high outcome prices, making plastic shot molding a perfect option for automation

Furthermore, the ability to create huge amounts consistently guarantees lower unit expenses, making it a cost-effective solution for businesses. This manufacturing performance not just satisfies market demands swiftly yet also improves the general competitiveness of producers in different markets. Plastic shot molding remains a preferred approach for high-volume manufacturing applications.

Style Versatility

The capabilities of plastic injection molding expand past high manufacturing effectiveness to include considerable design versatility. This manufacturing procedure permits engineers and developers to create intricate and detailed forms that may be difficult or difficult to accomplish with various other techniques (Plastic Injection Molding). The capability to conveniently adjust and change mold designs implies that producers can quickly react to altering market needs and introduce new item designs without substantial retooling

In addition, plastic shot molding sustains a vast variety of products, including different thermoplastics and thermosetting polymers. This range allows the production of parts with special properties, such as improved stamina, lightweight qualities, or certain thermal and electrical qualities. Additionally, the procedure enables the assimilation of several features right into a solitary part, reducing the need for assembly and minimizing potential points of failing.

The accuracy of shot molding additionally makes certain that elements are generated with limited resistances, improving fit and function. The adaptability to produce small to huge sets successfully further underscores its versatility, making it an optimal choice for both prototyping and large-scale manufacturing. In general, style flexibility is a foundation benefit of plastic injection molding, driving technology in various markets.

Cost-Effectiveness

Cost-effectiveness stands out as a considerable advantage of plastic shot molding in production. This process enables for the mass manufacturing of high-quality plastic components at a fairly affordable per device, particularly when contrasted to various other producing methods. The effectiveness of shot molding depends on its ability to produce complicated forms with marginal waste, enhancing material usage and minimizing general expenses.

In addition, the rate of production is a crucial consider cost-effectiveness. As soon as the preliminary mold and mildew is produced, the moment called for to create each subsequent component is substantially decreased, resulting in boosted output and faster turn-around times. This rapid production ability not just meets high-volume demands yet additionally lessens labor prices, as automated systems can manage a lot of the process.

Moreover, the resilience and go to my blog long life of injection-molded products contribute to their cost-effectiveness in time. These components often call for less maintenance and substitute, causing reduced lifecycle prices for end-users and makers alike. In recap, the cost-effectiveness of plastic injection molding makes it an attractive choice for services seeking to enhance their manufacturing effectiveness while maintaining product high quality.

Material Adaptability

Material flexibility is a trademark of plastic shot molding, allowing producers to pick from a large range of polymers that fulfill particular efficiency needs. This flexibility permits the production of parts tailored to different applications, varying from auto parts to consumer products.

Frequently utilized materials consist of acrylonitrile butadiene styrene (ABDOMINAL MUSCLE), polycarbonate Bonuses (COMPUTER), and polypropylene (PP), each offering unique homes such as effect resistance, warm tolerance, and chemical security. Suppliers can pick materials based upon features like strength, weight, and thermal stability, making sure completion item fulfills useful and aesthetic demands.

In addition, the ability to incorporate different polymers via co-injection methods further boosts material convenience. This enables the development of multi-layered elements with distinct characteristics, such as soft-touch surfaces incorporated with rigid structural elements.

In addition, improvements in recycled and biodegradable products are increasing the alternatives available, lining up with sustainability goals in manufacturing. On the whole, the diverse material selections in plastic injection molding empower manufacturers to introduce and enhance their items, promoting the development of extremely specialized and competitively useful remedies.

Boosted Item Sturdiness

Enhanced product resilience is just one of the substantial advantages supplied by plastic shot molding, as the production process enables for specific control over product residential properties and component design. This precision ensures that the final items show improved mechanical stamina and resilience, which are important factors in a variety of applications, from durable goods to commercial components.

Moreover, the elaborate geometries attainable with shot molding enable the production of components that can withstand stress and strain far better than traditional production methods. The consistent wall density and reduced product waste also contribute to the overall integrity of the product, decreasing the possibilities of failure during its lifecycle.

Verdict

To conclude, plastic shot molding presents substantial advantages in manufacturing, consisting of high manufacturing effectiveness, layout versatility, and cost-effectiveness. The approach's ability to quickly produce big amounts of the same parts while reducing labor and product waste is critical. Moreover, the adaptability in product selection adds to boosted product resilience and lower lifecycle prices. These variables jointly develop plastic injection molding as an ideal remedy for automation applications, attending to the dynamic demands of contemporary manufacturing atmospheres.

Plastic shot molding has actually emerged as an essential technique in the production market, using an array of advantages that considerably boost manufacturing processes.One of the most considerable advantages of plastic shot molding is its high manufacturing efficiency, which can result in the quick production of thousands of similar components within a short timeframe. Plastic Injection Molding.The capabilities of plastic injection molding expand past high manufacturing efficiency to incorporate significant design versatility.In verdict, plastic shot molding presents considerable benefits in production, including high production effectiveness, layout adaptability, and cost-effectiveness. These variables collectively establish plastic injection molding as an ideal remedy for mass production applications, resolving the vibrant needs of modern manufacturing environments